Comparison of Spray-Coated MEA

Comparison of Spray-Coated MEA – Ultrasonic Sprayer – Cheersonic

With the advancement of science and technology and the improvement of people’s living standards, electronic products such as mobile phones have gradually become necessities in people’s lives. These electronic products are becoming more and more abundant and their power consumption is increasing. Due to the limitation of energy density, traditional batteries have been unable to meet the requirements of emerging electronic products. Direct methanol fuel cell (DMFC) has emerged as a new type of energy conversion equipment. Direct methanol fuel cell has experienced more than 20 years of development, and its technology has become increasingly mature, but there are still problems of catalyst poisoning and methanol penetration. These two problems severely restrict the speed of its marketization. Aiming at the problem of methanol permeation, We compared with the MEA functions between spin coating and ultrasonic spray coating.

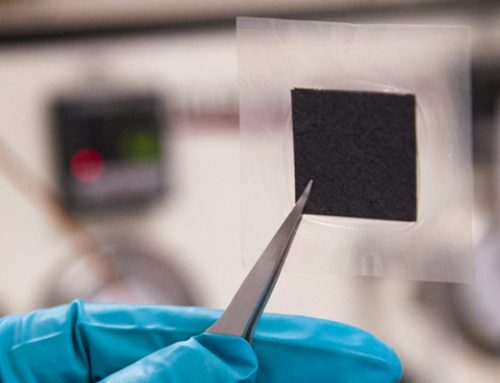

Spin coating and ultrasonic spraying gas diffusion electrode (Gas Diffusion Electrode, referred to as GDE) method and catalyst coated membrane (Catalyst Coated Membrane, referred to as CCM) method to prepare flexible MEA with carbon cloth as the diffusion layer material, by comparing the catalytic layer Different factors such as Nafion content, catalyst loading, hot pressure pressure, etc. It can clearly see some advantages of ultrasonic spraying.

Ultrasonic spraying can accurately control the Nafion content in the membrane electrode catalytic layer, reduce the thickness of the catalytic layer, and optimize the composition and structure of the MEA anode diffusion layer, and it allows large areas to be coated at high-speed with only minimal loss to coat catalyst suspension. However, the catalyst coating formed by spin coating has poor uniformity and different thicknesses. A slightly rough film appears on the periphery of the module, and more serious cracks and peeling. The waste of materials cannot be ignored.

Cheersonic has committed to the research and development of various ultrasonic equipment for more than ten years. CENG-S, CENG-M and CENG-L developed by our company is basic, programmable micro material spray coating system. Various types of catalysts suspensions including the carbon black ink, PTFE binder, ceramic slurry, platinum and other precious metal can be sprayed by using these equipment. Cheersonic ultrasonic dispersion syringe pump is 25 ml glass syringe standard, by controlling module delivers electrical impulses to generate ultrasonic vibrations inside of syringe body, and duration and intensity of ultrasonic vibrations is user controlled to completely disperse and hold particles evenly suspended in solution for up to several hours.