FOOD MANUFACTURING COATING SYSTEMS

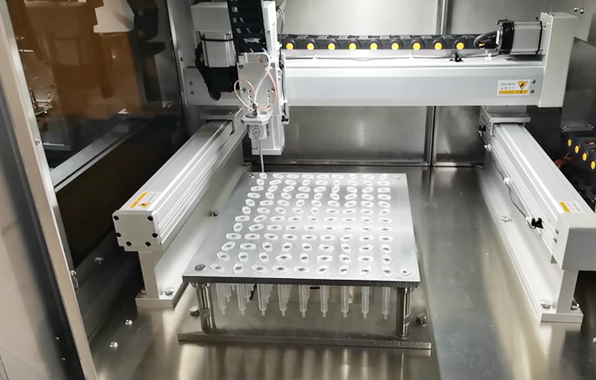

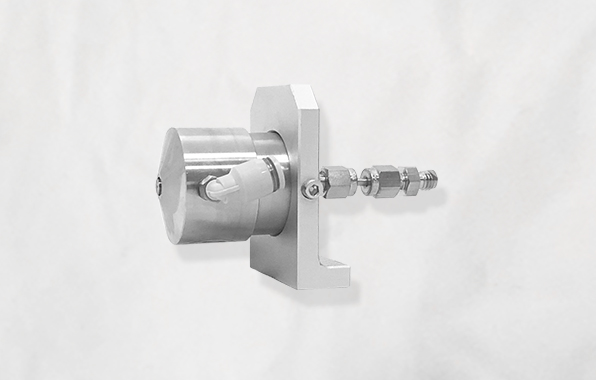

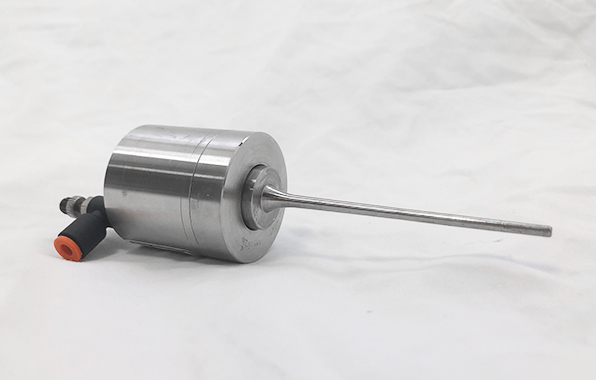

Ultrasonic nozzles feature a unique fine mist spray that greatly reduces overspray, saves costs and reduces air pollution. Ultrasonic Food Manufacturing Coating Systems are essentially non-blocking self-cleaning devices that use high frequency sonic atomization liquids instead of using high pressure to force liquid through small orifices. Ultrasonic nozzles open up more possibilities for food applications, and precise coatings allow the antimicrobial coating to be evenly applied to the surface of the product.

ANTIBACTERIAL COATING

Ultrasonic spray systems are ideal for spraying small amounts of antimicrobial coatings on foods to increase product safety and extend shelf life. Ultrasonic spray systems are capable of producing very thin nanoscale antimicrobial coatings that are not possible with other spray (deposition) methods. Ultrasonic coating systems use ultrasonic nozzle technology to produce very small, uniform droplets with very tight droplet distribution.

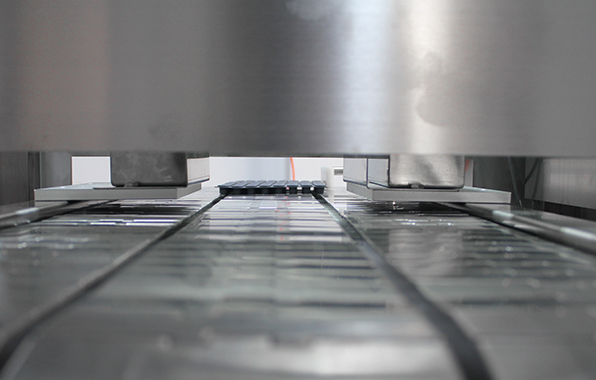

SEASONING COATING SYSTEM

Ultrasonic spray systems are ideal for spraying food flavoring solutions into foods such as cereals. The ultrasonic spray system is easy to integrate with existing conveyor systems. The ultrasonic spray equipment has a fast return on investment and no clogging, which greatly saves the spray material required for uniform coating.

FRESH COATING SYSTEM

Ultrasonic spraying involves spraying a small amount of additive onto the finished product before processing, rather than adding a large amount of additives before processing. Ultrasonic spray technology is used to ensure that the insurance solvent is evenly and densely covered on the entire surface of the food, reducing overspray, ensuring the spraying effect and reducing the use of insurance solvents.

Advantage:

- Flow controllable

- Precise, uniform, thin coating

- Proven to run continuously 24/7 under suitable conditions

- Reduce maintenance costs, reduce liquid usage by 50%, and reduce waste of raw materials

- Rapid return on investment

- Non-blocking ultrasonic nozzle

- Food grade design

- A wide range of sprayable solvents, water/oil/alcohol solvents, or suspensions of solid particles

- The droplets easily adhere to the surface of the product

- Flexible control of spray width

- Uniform film ensures the effectiveness of the applied material

Application:

- Antibacterial coating

- Fresh coating

- Seasoning paint

- Decorative glaze, egg coating

- Moisture-proof coating

- Health products, flavors and herbal extracts

- CBD (Cannabidiol) and THC oil coatings onto tea bags

To reach our anytime via email please fill out the form below with your request and a company representative will reply to you. To find your local CHEERSONIC representative to connect directly click your region in the contact drop down menu.

Contact CHEERSONIC For immediate assistance please contact us the corporate headquarters during business hours at 6:00 am – 22:00 pm.

Tel: 0571-87910406

- Mobile: +86 13588732518

- Email: Market2@cheersonic.com

Add: 11-13 Chuangye Road, Changkou, Fuyang, Hangzhou, Zhejiang, China