Improves Spraying EMI Shielding Capabilities

New ultrasonic coating system improves spraying EMI shielding capabilities

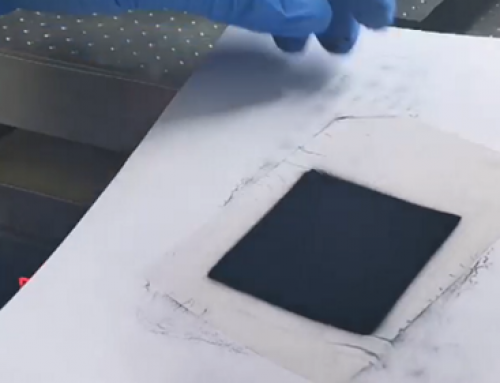

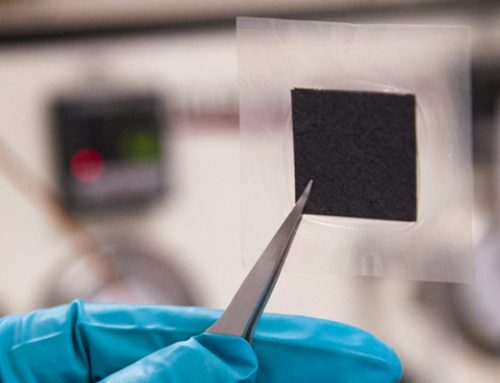

Cheersonic has developed a new UAM6000 ultrasonic coating system, which is specifically designed to conformally spray EMI (electromagnetic interference) shielding materials onto semiconductor packages. Because the nozzle of the equipment can be rotated, it can spray on the various surfaces and grooves of the special-shaped EMI, and the EMI shielding protection characteristics are improved, so this new coating equipment has attracted more and more attention. Ultrasonic coating is a cost-effective, fast and simple alternative to expensive sputter-based coating equipment.

The UAM6000 ultrasonic intelligent rotary coating system is specially designed and verified to spray copper and silver-filled shielding materials, and can accurately control the coating characteristics without excessive spraying.

Cheersonic ultrasonic nozzles are known for their low/maintenance-free, non-clogging, high uniformity and highly repeatable performance. Special ultrasonic nozzle configurations have been developed for these EMI applications to provide a more targeted spray area. Compared with all other spray types, this spray method can significantly reduce overspray. This new nozzle design cooperates with the highly controllable UAM6000 control system, making the device a complete coating solution for EMI shielding coatings.

UAM6000 ultrasonic intelligent rotary coating system functions include:

500×500 mm, infusion and syringe pump

Proprietary ultrasonic dispersion mixing system can ensure the stability of the solution over time

The throughput is significantly higher than the sputtering speed

Compatible with general spray solutions

The nozzle can be rotated to spray to achieve uniform shielding coverage on the top and side of the package

Top surface: side wall thickness ratio is 1: 0.6~0.7

in-line conveyor configuration for customers.

About Cheersonic

Cheersonic is a professional manufacturer in the development and application of liquid ultrasonic atomization technology into nozzle systems and spraying and coating application systems. Compared to conventional pressure spraying methods, the company’s ultrasonic nozzles do not clog, reduce liquid usage, waste, and environmental impact while achieving much more precise, uniform, thin film coatings. Cheersonic is continually developing new applications for its unique technology, replacing wasteful practices in a world that is growing ever more environmentally sensitive. For more information, visit the company at http://www.cheersonic-liquid.cn/.

Recommended Machine

UAL100 ultrasonic dispersion liquid supply system

UAM3000 Ultrasonic Stent Spraying Machine

UAM4000 small desktop ultrasonic spraying machine

UAM4000L Ultrasonic Precision Spraying Machine

UAM6000 Ultrasonic Large Spraying Machine

UAM7000 Ultrasonic Balloon Guide Wire Spraying Machine

UAM8000 ultrasonic assembly line spraying machine