Coated Glass

Coated glass has good decoration and energy saving functions, and is widely used in construction and automobile industries. With the development and utilization of new materials, the functions of coated glass will increase. The emergence of new film materials requires appropriate coating methods and processes. Ultrasonic spray pyrolysis is considered to be an effective method for coating various functional films on glass substrates. The process is to spray the solution containing metal ions onto the hot glass substrate through atomization. As the solvent volatilizes, the solute reacts on the substrate. (Thermal decomposition reaction) to form a thin film. Using this method can form a variety of films on the glass substrate, such as SnO2, InxOs, ZnO, CuzO), CdlS and other thin films.

Compared with other glass coating methods (evaporation, sputtering, ion coating, etc.), ultrasonic spray pyrolysis has the following advantages:

(1) The equipment is simple and the reaction is easy to control;

(2) The requirements for experimental conditions such as vacuum and air pressure are not high;

(3) The selection of raw materials is wide, and the composition and composition are easy to adjust;

(4) The coating layer is firmly bonded to the substrate and has good performance;

(5) Suitable for large-area coating, especially for online glass coating.

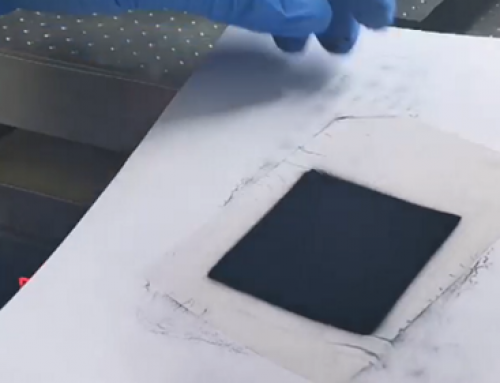

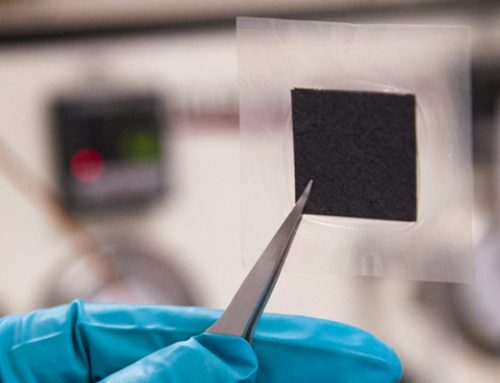

Touch Screen After Ultrasonic Spraying Video

https://www.youtube.com/watch?v=V7rJCeWmpfg

Recommended Machine

UAL100 ultrasonic dispersion liquid supply system

UAM3000 Ultrasonic Bracket Spraying Machine

UAM4000 small desktop ultrasonic spraying machine

UAM4000L Ultrasonic Precision Spraying Machine

UAM6000 Ultrasonic Large Spraying Machine

UAM7000 Ultrasonic Balloon Guide Wire Spraying Machine

UAM8000 ultrasonic assembly line spraying machine