Composite bipolar plate for fuel cell

Composite bipolar plate for fuel cell – fuel cell coating – Cheersonic

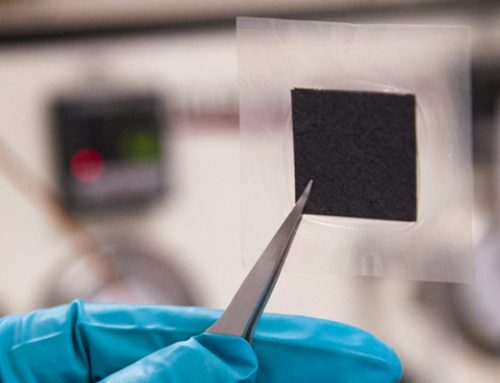

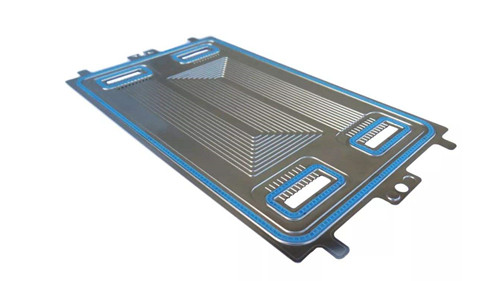

Compared with metal bipolar plates and graphite, composite bipolar plates combine the advantages of the above two types of bipolar plates, and have the characteristics of corrosion resistance, easy forming, small size, and high strength. It is one of the development trends of bipolar plate materials. . However, the current production of composite bipolar plates has high contact resistance and high cost, which is a problem that researchers are currently solving.

The composite bipolar plate material is generally composed of a polymer resin matrix and graphite and other conductive fillers. Among them, the resin as a reinforcing agent and adhesive can not only enhance the strength of the graphite plate, but also improve the gas barrier properties of the graphite plate. Some scientists use fluoroplastics and graphite to make composite materials, which have excellent mechanical strength, electrical conductivity, heat and corrosion resistance, and meet the requirements of fuel cells. However, this bipolar plate has a long production cycle and high cost, which is not suitable for commercial Chemical production; some scientists use graphite/vinyl resin to prepare bipolar plates. The bipolar plates have the advantages of low cost, high conductivity and simple preparation, but the production cycle is long and the stability is not good enough. In contrast, the use of a mixture of liquid crystal polymer and graphite, and the use of low-viscosity liquid crystal polymer injection molding bipolar plates, has high body conductivity and a short molding cycle.

The composite bipolar plate is made of thermosetting resin such as epoxy resin, which has excellent mechanical strength but high electrical resistance. The composite material is prepared with epoxy resin and expanded graphite, which shows lower electrical resistance, but the bending strength cannot meet the requirements. The bipolar plate made of carbon fiber/phenolic resin composite material has good electrical conductivity and mechanical properties, but the production process is complicated and expensive; powdered polyarylacetylene resin is used as the adhesive, graphite is used as the conductive filler, and mixed The polyarylacetylene/graphite composite bipolar plate was prepared by hot pressing. The results show that when the mass fraction of graphite in the composite bipolar plate is 70%, its overall performance in terms of density, conductivity, air permeability and bending is the best. In recent years, a high-performance carbon-carbon composite material is emerging. The mesophase carbon microspheres and carbon fibers are blended by the gel injection molding process to prepare a carbon-carbon composite bipolar plate. Stable performance and low production cost.

In summary, metal bipolar plate, graphite bipolar plate and composite bipolar plate materials have their own advantages and disadvantages. Graphite materials have good corrosion resistance and conductivity, but their processing costs are too high. Compared with graphite materials, composite materials have lower cost and good corrosion resistance, but the current conductivity of processed bipolar plates is low, which cannot meet the performance requirements of bipolar plates, and researchers need to further improve the conductivity of composite materials. Sex. On the premise of ensuring reasonable electrical conductivity, the coated metal bipolar plate significantly improves the corrosion resistance of the bipolar plate, which greatly increases the service life of the entire fuel cell system. However, the metal surface coating will undoubtedly increase the manufacturing cost and the complexity of the process. How to improve the service life of the bipolar plate on the basis of ensuring the corrosion resistance and electrical conductivity, and further reduce the cost and process complexity, is a metal double The next step of the plate needs to be solved.