Highly Flexible Reciprocating Flux Spraying System

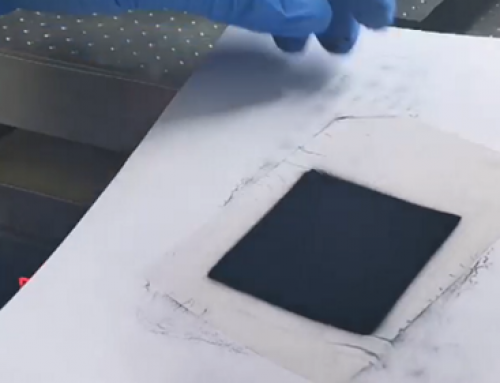

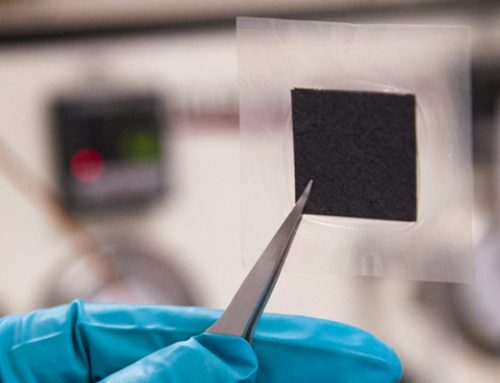

UAM8000 is a fully automatic and highly flexible reciprocating flux spraying system designed for high-volume production lines. It is suitable for manufacturers who need to change PCB width frequently and spray multiple flux types. UAM8000 can spray flux on PCBs with a board width of 2-24 inches and has a programmable selective soldering function, which provides ideal flexibility on a high-precision reciprocating platform.

UAM8000 can be easily installed in all wave soldering machines and control all process parameters through the touch screen. In addition to the selective flux function, UAM8000 also has 1000 recipe storage, high-precision flux delivery pump, and conveyor speed sensing options.

UAM8000 completes Cheersonic’s ultrasonic spray flux product line, including fixed systems and reciprocating systems, to meet the needs of any manufacturer. All Cheersonic spray flux equipment integrates a non-clogging ultrasonic nozzle, which can reduce the flux consumption by up to 80% and greatly reduce the overspray phenomenon. It only needs to be cleaned once a month and eliminates the use of thinner.

This new type of high-quality spray flux system has rapidly gained popularity due to its unique selective flux function and the overall value based on its performance in multiple manufacturing plants around the world.

About Cheersonic

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

The Company’s solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

Cheersonic’s growth strategy is focused on leveraging its innovative technologies, proprietary know-how, unique talent and experience, and global reach to further develop thin film coating technologies that enable better outcomes for its customers’ products and processes. For further information, visit https://www.cheersonic-liquid.cn/en/.