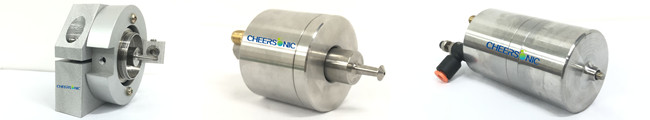

CENG-M Fuel Cell Catalyst Coating System

Product Description

Cheersonic’s CENG-M ultrasonic equipment is suitable for spraying catalyst solutions containing carbon black ink suspension, platinum slurry and other precious metal solutions. It can prepare fuel cell proton exchange membrane with excellent performance. It integrates multiple systems such as ultrasonic, dispersion, carrier gas, liquid, heating station, vacuum adsorption, and exhaust emission control. It is suitable for R & D, small and medium-sized batch production. Using the company’s patented ultrasonic spray head technology, it can spray uniformly and efficiently on proton exchange membranes and gas diffusion layers. Due to the characteristics of controllable film thickness and high uniformity, the durability and conductivity of the film electrode can be greatly improved. And because the equipment has the advantage of extremely high liquid utilization, it can greatly reduce research and production costs.

Key Features

• Full range of ultrasonic nozzles

• Titanium alloy and stainless-steel construction, corrosion resistance

• The nozzle is not easy to be blocked

• Utilization> 95%

• Low diversion pressure can reduce waste of overcoating and air pollution

• Ultrasonic dispersion liquid system- keep the suspension evenly dispersed during spraying

• Spraying proton exchange membrane with high uniformity and good adhesion

• The particle diameter is optional which can more flexibly affect the through-hole property of the coating

• Heating plate, vacuum plate or combination of heating plate and vacuum plate

Application

• PEM

• GDL

• Electrode

• Electrolyte materials

• SOFChttps://www.youtube.com/watch?v=gzvvEhZdLZ4

Parameter

| Ultrasonic spraying system |

Frequency: 50khz, 60khz, 120khz Spraying width: 80mm Particle content: <10% Particle size: 10-40um |

Liquid delivery(optional) | Ultrasonic dispersing syringe, Keep the suspension evenly dispersed during the spraying process |

| Nozzle alignment | Laser assisted alignment | Material of liquid tube | PTFE |

| Liquid utilization rate | 95% | Heating substrate(optional) | Maximum temperature: 400℃ |

| Spray uniformity | 5% | Temperature | 0-40℃ |

| Work area | 450 x 450 mm (17.71” x 17.71”) | Certifification | CE, ISO9001:2015 |

| Speed |

XY: 300mm/sec Z: 50mm/sec |

Compressed air |

551.6 kPa (80 PSI) dry unlubricated air |

| Syringe pump |

Flow rate: 0.01- 50ml/min One syringe: up to 100ml Two syringe: up to 50ml each |

Power requirements |

220V, +/-10%, 50-60Hz, single phase |

| Control system | Self-developed 6-axis control system, 7-inch full-color touch LCD screen, can be set to automatic mode, jog debugging mode, with security system | Vacuum adsorption(optional) |

150C heat/vac Power of vacuum pump: <500w Pumping speed: ≥60L/min |

| Motion accuracy | ±0.1mm | Dimensions | 1400L*900W*1600G mm |

| Motors | Digital AC servo motor drive | Weight | 650kg |