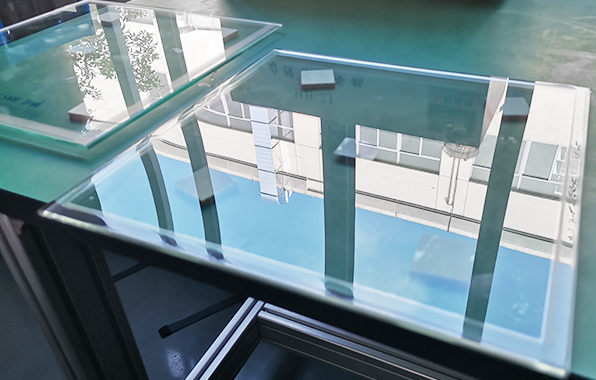

ULTRASONIC GLASS COATING SYSTEMS

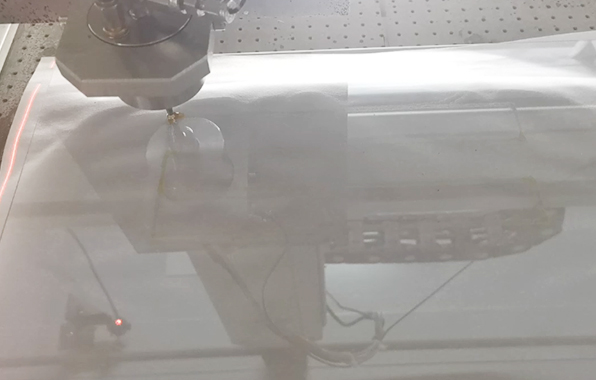

Ultrasonic Coating Systems are capable of spraying very thin layers of anti-stain and other protective materials on glass of any width without dripping and rebound. In addition, ultrasonic spray systems offer unique advantages over traditional vacuum deposition when spraying nanosuspensions such as transparent conductive oxides. With the development of the glass industry, including the chemical composition of conductive coatings such as TCO and electrophoresis on glass panels, Cheersonic will continue to provide innovative ultrasonic coating solutions to manufacturers around the world. Our ultrasonic spray technology offers unique advantages in coating a uniform coating of liquid suspensions containing functional nanoparticles.

TOUCH SCREEN

Ultrasonic spray has significant advantages over other coating methods for functional glass coatings such as Transparent Conductive Oxide coatings.

- Utilization rate of solution reaches 95% and above

Very thin, uniform, durable layers

- High control accuracy, spot spraying and fast startup speed

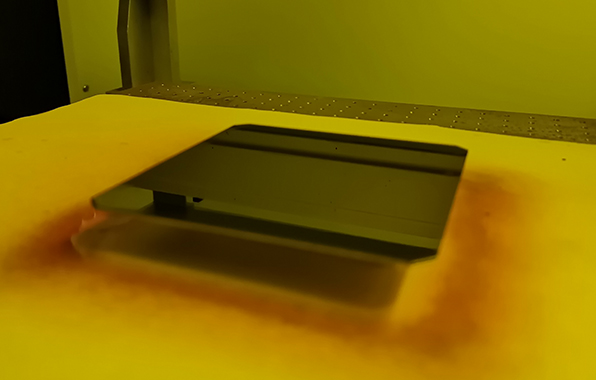

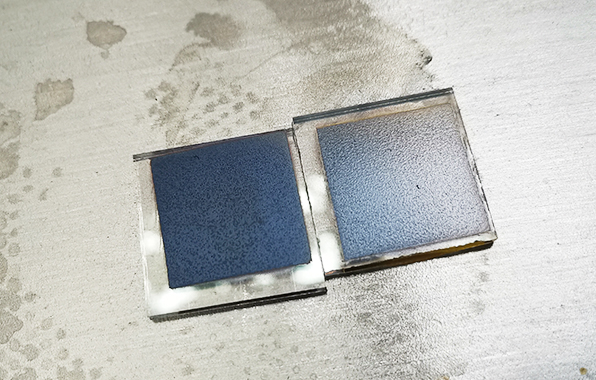

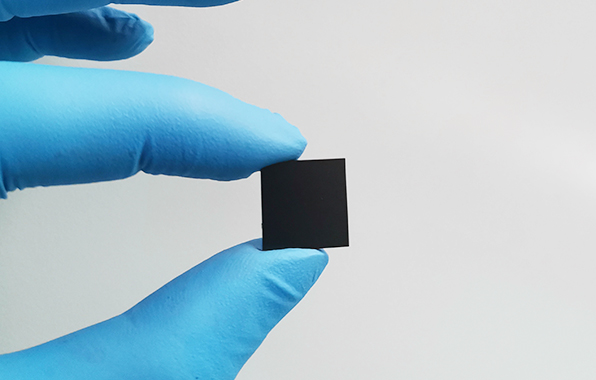

FUNCTIONAL COATINGS

Ultrasonic spraying of functional glass coatings (e.g., transparent conductive oxide coatings) has significant advantages over other coating methods.

- High uniformity across large areas

- Uniform dispersion of particles results in larger active surface area, creating greater electrical performance with thinner layers.

- Highly controllable spray enables selective area coating processes not possible with other coating methods.

Advantage:

- Environmentally friendly spraying

- Material consumption reduced by up to 80%

- The spray results are consistent

- Ability to spray nanomaterials

- Minimal repair and downtime

- Highly uniform nano film

- Precision, non-clogging ultrasonic spray technology is proven in solar glass manufacturing processes

- Precise control of coating thickness

Application:

- Transparent conductive oxide

- Anti-reflection

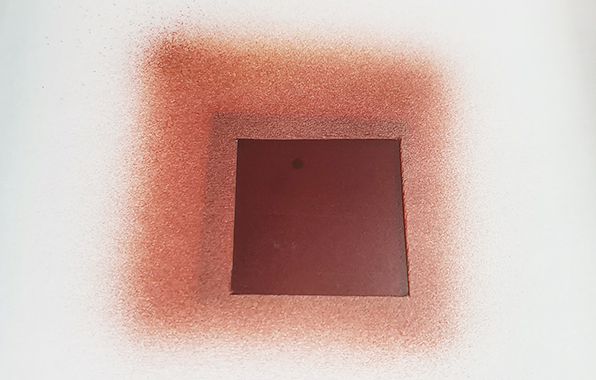

- Apply an anti-acid solution to the float glass

- Scratch resistant

- Photoresist

- Carbon nanotube film

- Optical coating

- Electrochromic coating

Photochromic coatings

- oleophobic (anti-fingerprint) coating

- Protective polymer coating on float glass

To reach our anytime via email please fill out the form below with your request and a company representative will reply to you. To find your local CHEERSONIC representative to connect directly click your region in the contact drop down menu.

Contact CHEERSONIC For immediate assistance please contact us the corporate headquarters during business hours at 6:00 am – 22:00 pm.

Tel: 0571-87910406

- Mobile: +86 13588732518

- Email: Market2@cheersonic.com

Add: 11-13 Chuangye Road, Changkou, Fuyang, Hangzhou, Zhejiang, China