ULTRASONIC SPRAYING ENERGY MATERIALS

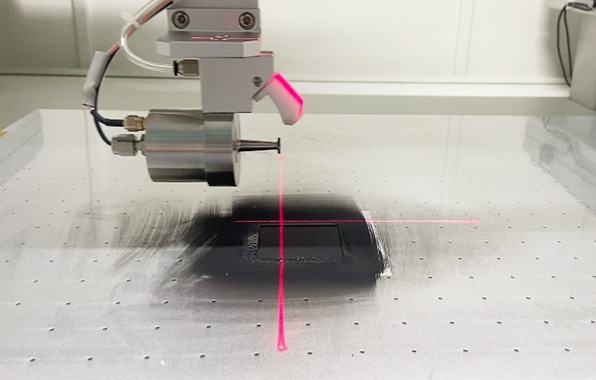

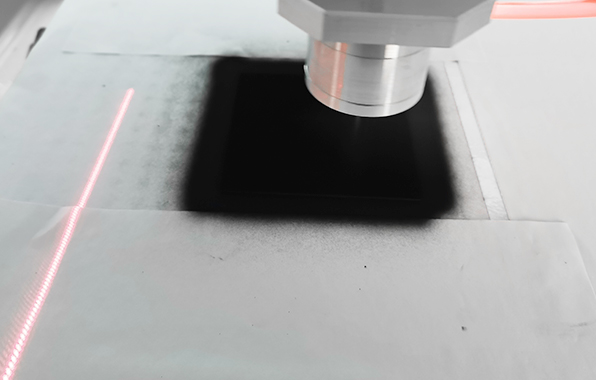

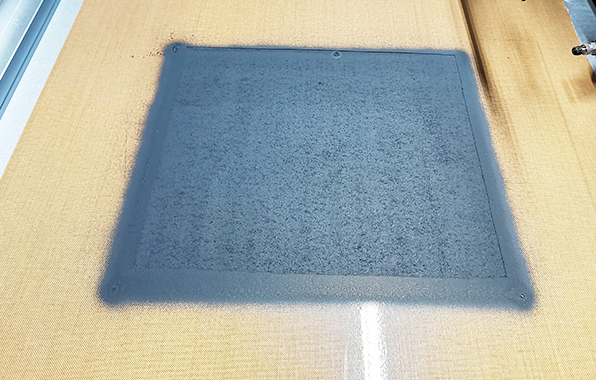

Ultrasonic spraying is ideal for deposition of solar cells, fuel cells, silicon cell coatings, and is increasingly used in research and production of spraying processes. Ultrasonic Spraying Energy Materials technology can be used to deposit uniform and extremely thin coatings on substrates of any width. Ultrasonic spraying technology enables very thin coatings with extremely high uniformity, resulting in improved electronic conversion rates and transport.

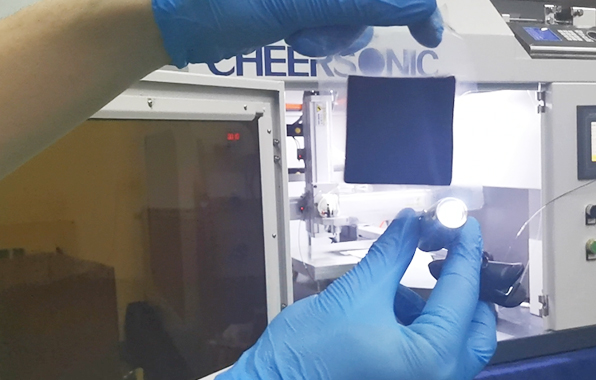

FUEL CELL

Ultrasonic fuel cell catalyst coating systems are uniquely suited for these challenging applications by creating highly uniform, repeatable, and durable coatings.

- Utilization> 95%

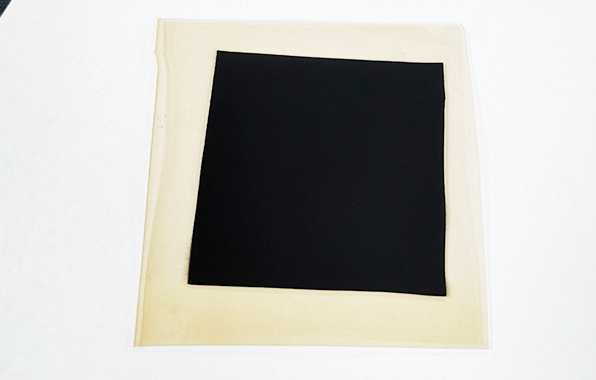

- Spraying proton exchange membrane with high uniformity and good adhesion

- The particle diameter is optional which can more flexibly affect the through-hole property of the coating.

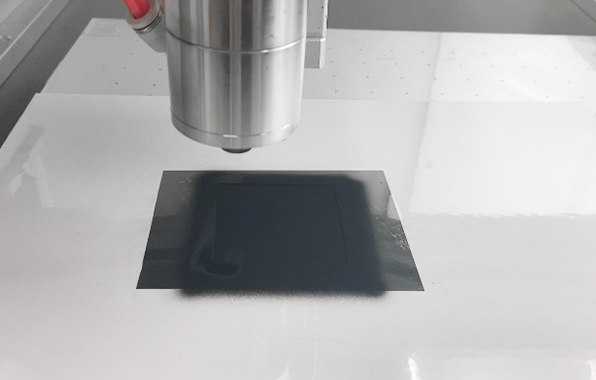

THIN FILM SOLAR CELL

Ultrasonic spray technology has been proven successful for depositing thin film solar cell coatings of anti-reflection layers, TCO coatings, Buffer layer coatings, PEDOT, and active layers in thin film solar cell manufacturing.

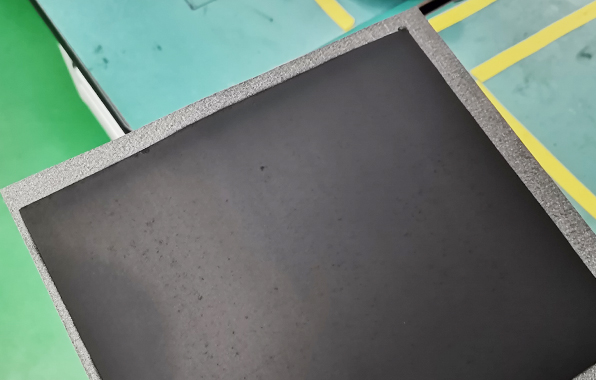

- High-uniformity film

- Clean, precise spray patterns that are easily shaped for various applications.

- Easy to adjust and repeatable coating parameters.

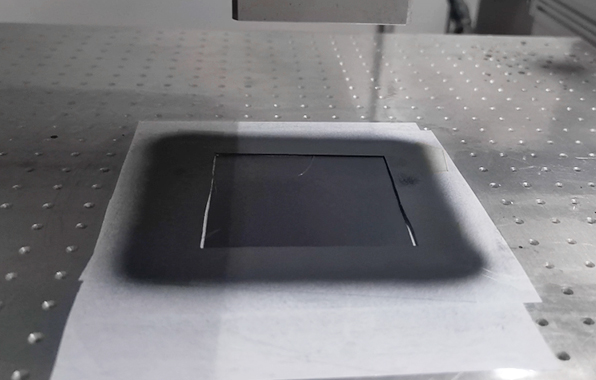

SILICON SOLAR CELL

Ultrasonic spraying systems provide a low-cost solution for many solar cell applications. One of the typical applications is to spray anti-reflection and anti-reflection films on solar cell glass panels.

- Titanium alloy and stainless-steel construction, corrosion resistance

- Low diversion pressure can reduce waste of overcoating and air pollution

- Highly controllable spray that produces reliable, consistent results.

Advantage:

80% reduction in material consumption

- Reduce waste and air pollution

Reduced maintenance and downtime

Spraying Precision Coating

Highly controllable spraying produces reliable, consistent results

No blockage

Ultra-low flow capacity for intermittent or continuous operation

High-uniformity film

Very tight droplet distribution (select droplet size based on nozzle frequency)

- During the spray process, ultrasonic vibrations disperse the suspended agglomeration particles

Application:

- Fuel cell

Thin film photovoltaic cells

Thin Film Solar Coatings

Calcium and titanium solar cells Cigs/czts Solar cell CdTe Solar cell

- Organic solar cells

- Carbon nanotubes/nanowires

- Graphene coating

- Anti-reflective coating

- Solar Glass Manufacturing

- Silicon photovoltaic cells

To reach our anytime via email please fill out the form below with your request and a company representative will reply to you. To find your local CHEERSONIC representative to connect directly click your region in the contact drop down menu.

Contact CHEERSONIC For immediate assistance please contact us the corporate headquarters during business hours at 6:00 am – 22:00 pm.

Tel: 0571-87910406

- Mobile: +86 13588732518

- Email: Market2@cheersonic.com

Add: 11-13 Chuangye Road, Changkou, Fuyang, Hangzhou, Zhejiang, China