Ultrasonic Spray System

Product Description

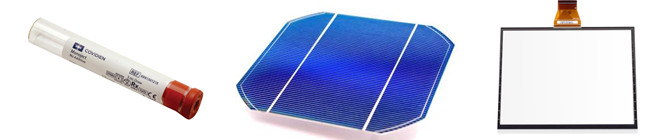

Ultrasonic Spray System has been in a wide range of industrial and R & D applications to replace the pressure spray, and to prevent sputtering problems. And Desktop Ultrasonic Spraying Machine atomization head using high-frequency sound wave atomization liquid, rather than using high pressure to force the liquid through the hole, so essentially with automatic cleaning function, will not plug. Ultrasonic blood collection tube spraying equipment to control the amount of waste caused by environmental pollution has been greatly reduced by 80%, and its unique fine mist droplets, greatly reducing the spray, eliminate waste, save money, but also reduce air pollution.

Feature

• Self-developed 6-axis controller

• Switzerland to introduce high-tech, the development of a new generation of ultra-fine particles 120K ultrasonic nozzle

• Spray nozzle and sprayed objects can be moved / rotated

• Ultrasonic spray distance is controllable

• Any nozzle can be unloaded / replaced

Advantage

• Atomization spray patterns are easy to mold for precise coating applications

• Highly controllable, controllable spray results and consistent error

• Corrosion-resistant construction utilizes titanium and stainless steel to avoid corrosion

• Low flow, gentle atomization, 80% less waste

• No clogging

• Reduce downtime during manufacturing

• The droplet size is as small as 13 microns, depending on the frequency of the ultrasonic wave

• Ultrasonic spray technology is used to coat virtually any substrate shape, size, or surface with even micron-thick coatings, even nano-coating thicknesses

Applications

• Three-dimensional painting

• Plane spraying

• Moisturizing

• Spray drying

• Dust off

https://youtu.be/FGH6hw1esNw

Technical Parameters

| Desktop Ultrasonic Spraying Machine | |

| Frequency | 40khz-120khz |

| Material | Horn Titanium Alloy + Shell Stainless Steel |

| Spray Particle Diameter | ≥0.6pl |

| Maximum Viscosity | ≤450cPs |

| Temperature | <40℃ |

| PH | Ph4-11 |

| Coating Thickness | 0.6μm-10μm |

| Sprayed Shape | Plane/Circumferential Surface |

| Spray Diameter | 3mm-80mm |

| Spray Speed | The test tube as an example 1000 per hour |

| Solid Content Range | ≤10% |

| Whether The Gas | YES |

| The Gas Pressure Range | 0.1μpa-0.3μpa |

| Control System | Six-axis Control System |

| Size | |

| Weight | |

| Voltage | 220V |

| Installation Aperture | ≥25mm |

| Injection | ≥0.3ml/min |

| Power Consumption | 0.2A |

| Rated Power | 3kw |