MEDICAL COATING SYSTEM

Ultrasonic nozzles are particularly suitable for a wide range of medical coating applications due to their very precise, non-blocking, repeatable spray performance and extremely low flow rate capability. For several years, Cheersonic has been providing ultrasonic medical coating system to medical device manufacturers worldwide. As medical device technology evolves, we will continue to design unique medical coating ultrasonic spray solutions to enhance patient safety and provide the highest quality medical device coating on the market.

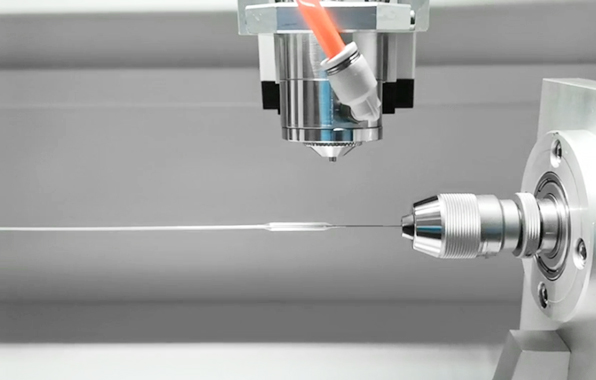

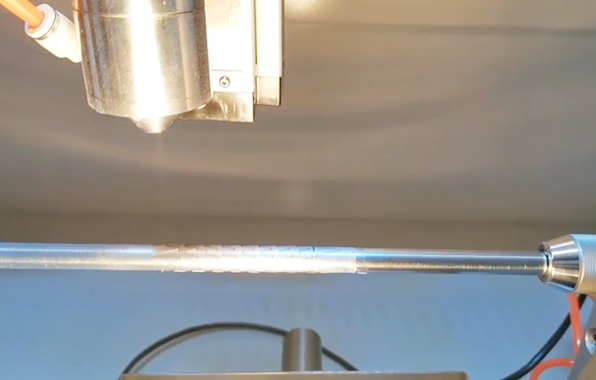

STENT

Ultrasonic drug stent coating machine is a high-performance stent spraying equipment developed for stent series products, mainly used for drug coating on the surface of stents.

- The liquid medicine utilization rate reaches 95% and above.

- The maximum diameter of the stent is 60mm, and the maximum length can be extended to a fixture of 100mm.

- Compared with dip coating, ultrasonic spraying will be much thinner, saving paint and avoiding waste.

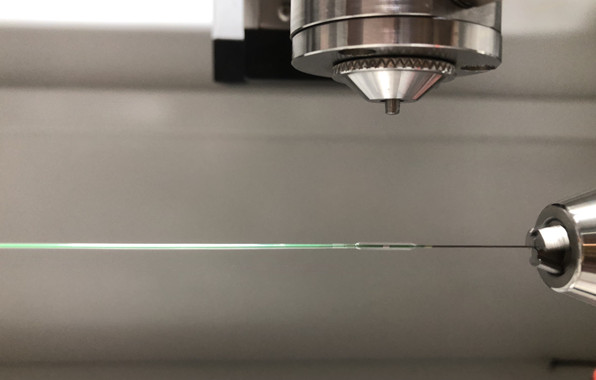

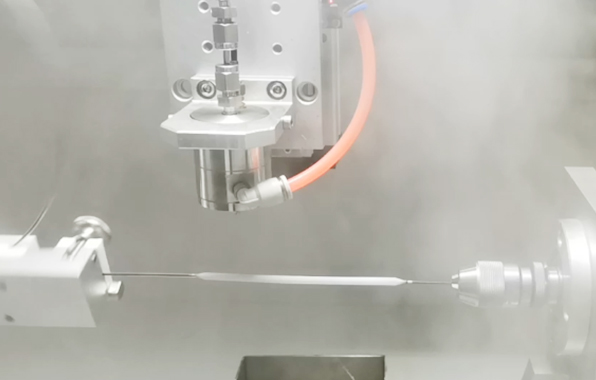

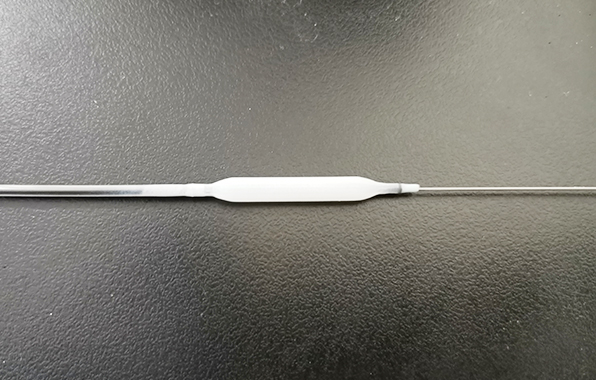

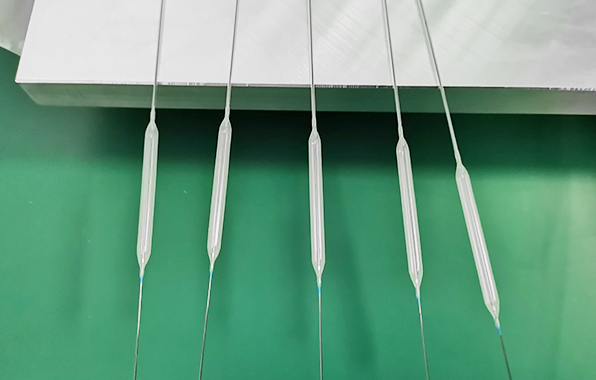

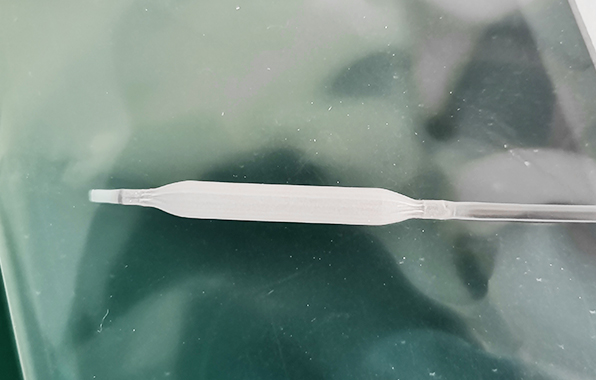

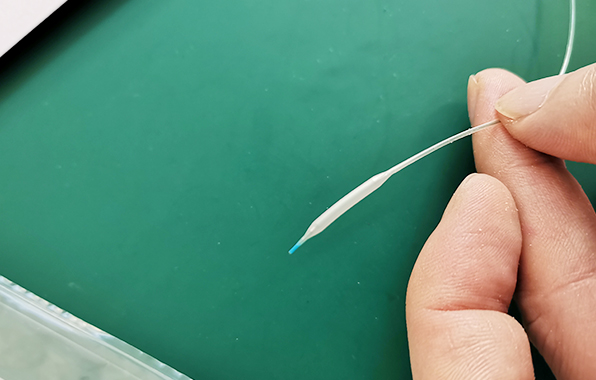

BALLOON CATHERTER

Ultrasonic balloon catheter coating machine provides a uniform drug coating for the balloon catheter through ultrasonic spray technology.

Effective spraying length: 280mm

- The utilization rate of liquid medicine is as high as 95% and above

- The finished and semi-finished balloons can be sprayed

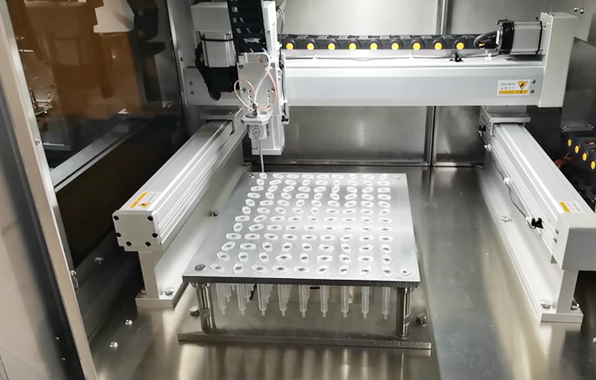

BLOOD COLLECTION TUBES / SYRINGE BARRELS

Desktop ultrasonic penetration spraying equipment is suitable for spraying on the inner wall of the tube.

- Highly uniform coating on tube walls

- Uniform dispersion of any solids contained in liquid

- Manipulation of ultrasonic atomizer accurately in and out of tube inner diameter

BIOSENSOR

Cheersonic’s ultrasonic biosensors coating systems are widely used in the preparation of nano- and sub-micron functional thin film coatings.

- Coating thickness: from nanometers to tens of microns

- Adjustable surface roughness: matt or smooth surface

- Coating thickness: from nanometers to tens of microns

MEDICAL TEXTILES

Cheersonic’s ultrasonic medical coating systems have been used to apply a wide variety of antimicrobial or other medical bandage coatings.

- Wide range of flow rate capabilities

- Flexible width control for various width products

- It can achieve uniform distribution and precise dose spraying, so as to effectively carry out drug delivery and treatment

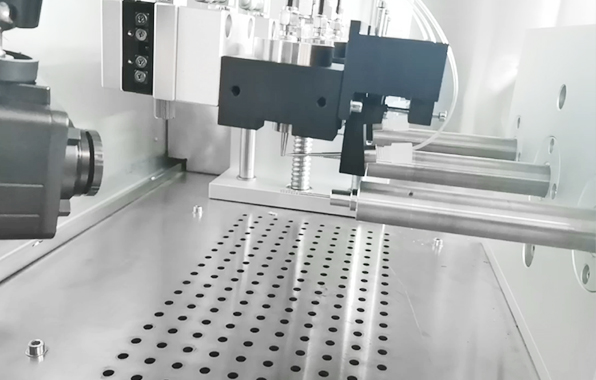

IN VITRO DIAGNOSTIC DEVICES

Ultrasonic spray coatings are highly controllable, offering very high transfer efficiency for precise thin films of solutions or suspensions such as biopolymers, proteins, EDTA, Heparin, amino acids, enzymes.

- Reduce overspray

- Anti-clogging design reduces maintenance and downtime

- Highly controllable spray

Advantage:

- Excellent uniformity

- Self-cleaning, ultrasonic nozzles prevent blockage

- Minimal repair and downtime

- Highly controllable spray produces reliable, consistent results

- Corrosion resistant titanium and stainless steel construction

- Ultrasonic nozzles can be sprayed on typical solvents and polymers for medical coatings

- Highly controllable and repeatable spray technology

- Ability to spray at flow rates as low as 5 microliters per minute

- The droplet size is as small as 13 microns (aqueous) and the droplets are very densely distributed

- Low speed spray adheres to the bracket without overspray, avoids overspray (reduces waste), and reduces material consumption by up to 80%

- Highly durable coating does not peel off

Application:

Drug-eluting heart, peripheral and arterial stents

- Catheter

- Medical device coating

- Medical textiles / bandages

- Blood collection tube and syringe

- Diagnostic equipment coating

- Bracket

- Orthopedic implants

- Guide wire

- Antibacterial coating

- Drug eluting balloon

- Blood collection tube and syringe

- Drug spray drying

- Protein, enzyme and reagent coatings

To reach our anytime via email please fill out the form below with your request and a company representative will reply to you. To find your local CHEERSONIC representative to connect directly click your region in the contact drop down menu.

Contact CHEERSONIC For immediate assistance please contact us the corporate headquarters during business hours at 6:00 am – 22:00 pm.

Tel: 0571-87910406

- Mobile: +86 13588732518

- Email: Market2@cheersonic.com

Add: 11-13 Chuangye Road, Changkou, Fuyang, Hangzhou, Zhejiang, China