NANOMATERIAL COATING SYSTEMS

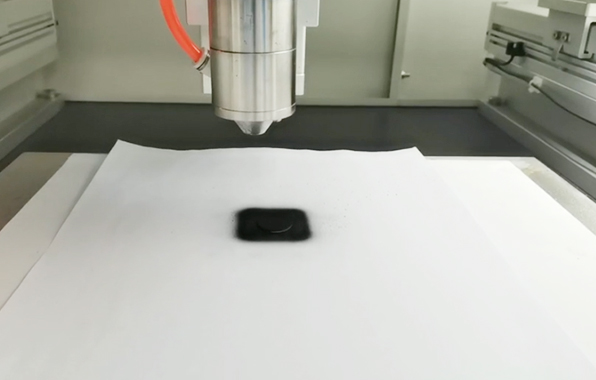

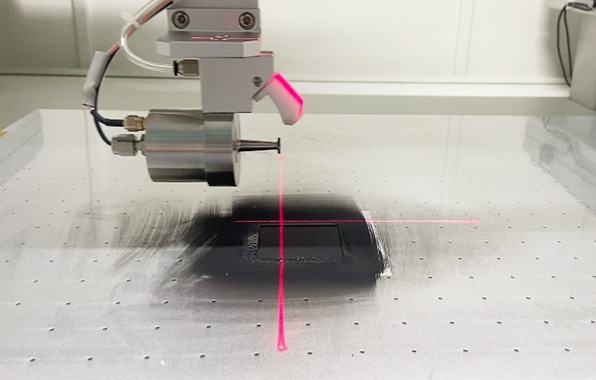

Nano-coating is a field of rapid development of ultrasonic coating technology. Ultrasonic Nanomaterial Coating Systems is ideal for depositing nano-coatings and is increasingly used in research and production spray processes. Ultrasonic spray technology can be used to deposit uniform nano-coatings on substrates of any width. Ultrasonic spray technology enables these very thin coatings to be produced with extremely high uniformity, even in a very wide range, for unique nano applications. Ultrasonic nanomaterial coating systems are uniquely suited to spraying nanosuspensions like CNTs, nanowires, perovskite, graphene, and others.

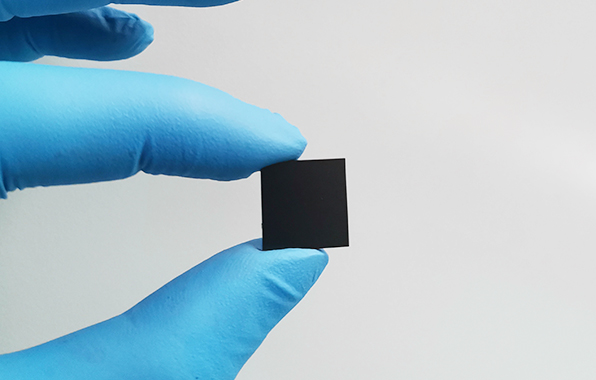

NANOWIRE

Ultrasonic sprayers can be used to spray nanowires, conductive inks or suspensions, and spray to form a uniform nanowire coating.

- Titanium alloy and stainless-steel construction, corrosion resistance

- Low diversion pressure can reduce waste of overcoating and air pollution

- The particle diameter is optional which can more flexibly affect the through-hole property of the coating

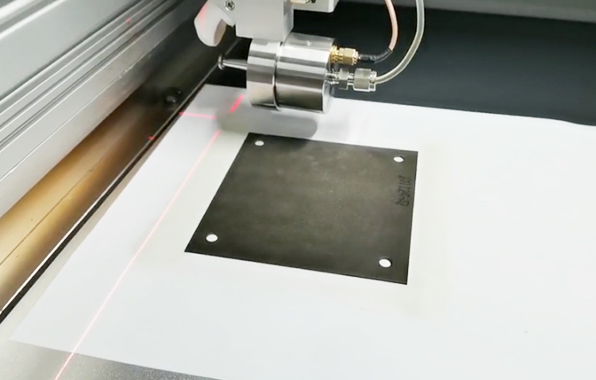

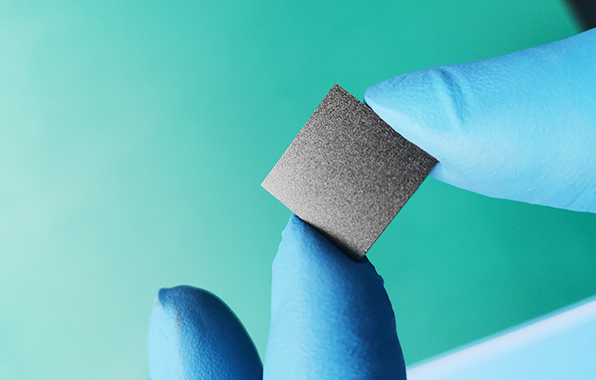

GRAPHENE

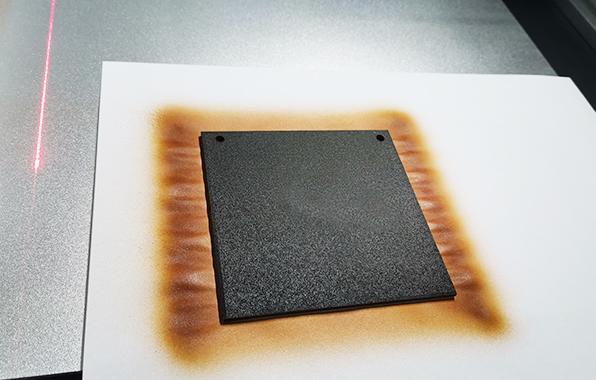

Ultrasonic spraying is capable of depositing highly uniform, extremely thin nanolayers with minimal overspray.

- Homogeneous distribution of nanoparticles over substrate for maximum use of materials

- Programmable XYZ coating systems provide a full solution for your coating process

- The particle diameter is optional which can more flexibly affect the through-hole property of the coating

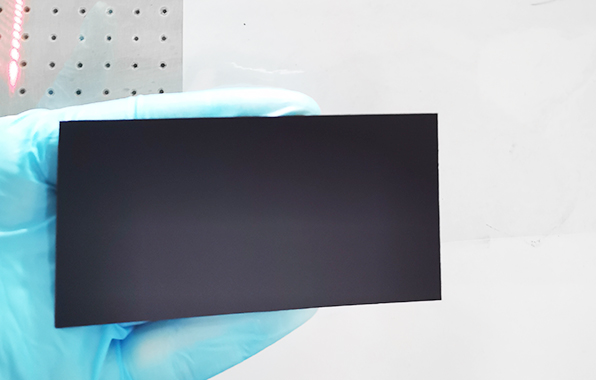

NANOSUSPENSION

Ultrasonic sprayers are particularly suitable for spraying nanosuspensions due to the inherent ultrasonic vibration of the nozzle during atomization.

- Fine line or wide area nanocoatings

- Choice of drop size, down to 13 microns, depending upon nozzle frequency used

- The ability to spray ultra-thin conductive layers with desired electrical and transparency characteristics

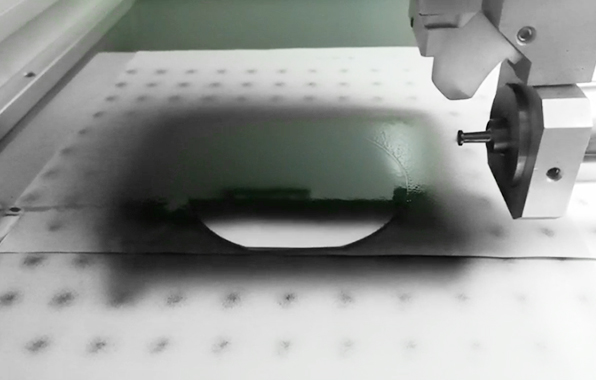

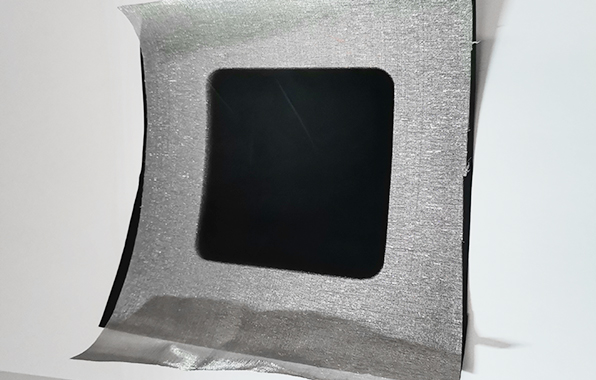

CARBON NANOTUBE

Ultrasonic spraying is used to spray carbon nanotubes to create a uniform coating in energy, electronics or other nanotechnology applications.

- Targeted low velocity spray results in very little overspray of expensive materials

- Ultrasonic coating systems give more flexibility, control, and more cost effective than other deposition methods such as dip, spin, and traditional spray

- From R&D lab scale through production volume manufacturing

Advantage:

- Soft, pressureless ultrasonic spray does not damage delicate structures

- Non-blocking, highly controllable spray

- Low flow is possible

- Reduces effective chemical usage by more than 95%, with minimal overspray

- Fine line or wide area nanocoatings

- Ability to deposit highly uniform, extremely thin nanolayers

- Spraying suspended particles with a certain dispersion and depolymerization function

- The size of the droplet depends on the spray frequency

- Ultrasonic spray systems are simpler and more cost effective than other deposition methods such as CVD or vapor deposition

- The ability to spray ultra-thin conductive layers with desired electrical and transparency characteristics

Application:

- Deposit carbon nanotubes and nanowires in a uniform, extremely thin coating to replace existing energy, electronics, semiconductor or medical applications

- Spraying catalyst inks in fuel cell manufacturing

- Coating solar cell substrates with active chemicals containing metal oxides

- Spraying transparent conductive oxide (TCO) chemicals in the touch screen manufacturing process

- Deposit uniform nanowires or graphene films in advanced electronic applications

- Anti-reflective coating onto solar glass

- Anti-stain or other protective coating on float glass

- Anti-scratch coating onto lenses or other lenses

To reach our anytime via email please fill out the form below with your request and a company representative will reply to you. To find your local CHEERSONIC representative to connect directly click your region in the contact drop down menu.

Contact CHEERSONIC For immediate assistance please contact us the corporate headquarters during business hours at 6:00 am – 22:00 pm.

Tel: 0571-87910406

- Mobile: +86 13588732518

- Email: Market2@cheersonic.com

Add: 11-13 Chuangye Road, Changkou, Fuyang, Hangzhou, Zhejiang, China