TEXTILE COATING

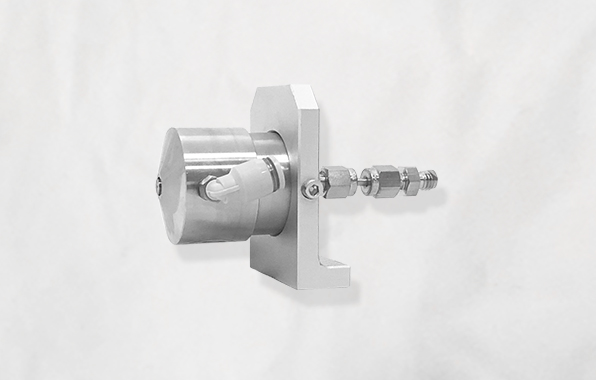

Ultrasonic spraying machine using ultrasonic nozzle technology, can produce very small, uniform droplets, with a very tight droplet distribution. Compared with the pressure nozzle, the nozzle orifice is large and is designed to be a non-clogging pressure-free spray device. This makes the ultrasonic sprayer flow rate controllable range is large, and ultrasonic spraying machine can prepare a very uniform very thin coating, saving spraying materials and improve the quality of fabric coating, through a more uniform coating to deal with the performance of the product.

MEDICAL TEXTILE

Cheersonic’s ultrasonic medical coating systems have been used to apply a wide variety of antimicrobial or other medical bandage coatings.

- Wide range of flow rate capabilities

- Flexible width control for various width products

It can achieve uniform distribution and precise dose spraying, so as to effectively carry out drug delivery and treatment

ADVANCED TEXTILES

Ultrasonic sprayable coatings include antifouling agents, water repellents, antibacterial agents, and flame retardants.

- Precise, repeatable, controlled deposition coatings

Very small, atomized droplets with uniform particle sizes create uniform nanolayer films

- Non-clogging ultrasonic nozzles reduce downtime for maintenance

Advantage:

- Accurate, repeatable and controllable deposition coating

- No blockage of ultrasonic nozzles reduces maintenance downtime

- Reduce waste (up to 80%)

- Reduce environmental pollution, reduce excessive spraying, reduce or eliminate wastewater treatment

- Can provide a very efficient coating process

- Self-cleaning ultrasonic nozzles to prevent blockage

- Excellent atomization spray effect, reducing the use of materials (far lower than soaking or other application methods)

- Uniform film ensures the effectiveness of the applied material

- Accurate coating allows the release of antimicrobial compounds evenly onto the applied surface

Application:

- Gloves

- Surgical Masks

- Bandages

- Wound dressing

- Hospital Textiles

- Surgical Gauze

- Carpets

- Dust-proof fabric

- Fireproof Fabric

- Waterproof Fabric

- Various other textile and Nonwoven textiles

To reach our anytime via email please fill out the form below with your request and a company representative will reply to you. To find your local CHEERSONIC representative to connect directly click your region in the contact drop down menu.

Contact CHEERSONIC For immediate assistance please contact us the corporate headquarters during business hours at 6:00 am – 22:00 pm.

Tel: 0571-87910406

- Mobile: +86 13588732518

- Email: Market2@cheersonic.com

Add: 11-13 Chuangye Road, Changkou, Fuyang, Hangzhou, Zhejiang, China