CGLS-M Glass Spraying Equipment

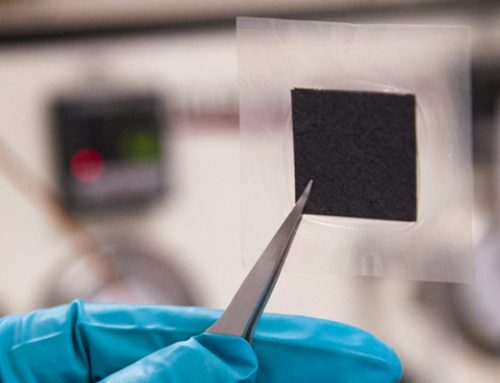

Cheersonic has many years of industry experience in the field of glass spraying. Ultrasonic spraying technology is regarded as a new and efficient and low-cost glass coating process. Compared with traditional roll coating, dip coating, two-fluid spraying and other processes, ultrasonic spraying can produce a more uniform and smooth film coating. Compared with vacuum coating processes such as vacuum evaporation and CVD, the ultrasonic spraying process has significant cost advantages. Cheersonic’s ultrasonic precision spraying system can provide a variety of glass surface functional film preparation solutions such as hydrophilic, hydrophobic, AR anti-reflection, heat insulation, transparent conductive film, TCO.

Application

• Flat glass

• Photoresist

• Touch screen

• Display

• Photovoltaic glass

Features & Benefits

• Uniform and controllable film layer

• Film thickness can reach nanometer level

• High uniformity

• High liquid utilization

• Can meet experimental and production needs

• Flexible customized solutions