In Vitro Diagnostic Devices

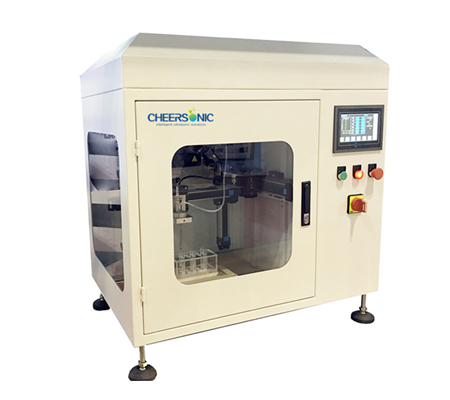

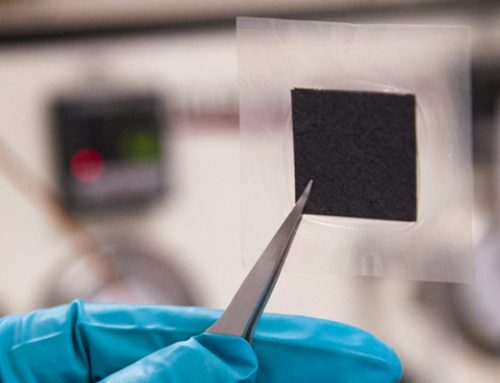

Ultrasonic nozzles can spray in any direction, coating target areas, complex 3D-shaped equipment and small components, and almost no excessive spraying. The typical application are two major directions: First, a series of sonication, such as mixing, breaking, and dispersing can be performed on physiological samples such as blood and saliva through a uniquely designed ultrasonic transducer, which is the key pre-processing of in vitro diagnosis, especially for the molecular diagnosis instrument. Second, the ultrasonic spray coating system of Cheersonic can be used to prepare various functional coatings for biosensors and microfluidic chips, such as bioactivity layers, hydrophilic coatings and conductive layers, etc.

Cheersonic provides ultrasonic sonic treatment devices and solutions for many well-known international in vitro diagnosis companies, including comprehensive customized services such as the research & development, design, production, detection of ultrasonic transducers, ultrasonic generators, kits and sample containers. With the unique acoustic matching layer technology of Cheersonic, high-performance non-contact acoustic cavitation processing can be achieved so that efficient mixing, dispersion, and breaking of samples such as blood, saliva and suspended particles can be realized.

Some examples of applications:

• Laboratory chip

• Reagent coating on microfluidic and microarray devices

• Instant diagnosis and test suite

• Cell culture container

• Blood glucose monitor

• Blood collection and analysis device

• Molecular and protein diagnostic kits

• Immunoassay kit

Advantage:

• Reduce overspray

• Anti-clogging design reduces maintenance and downtime

• Highly controllable spray

• Uniform and uniform coating

• Able to spray ultra-thin, clear lines

• Will not damage or change cell structure

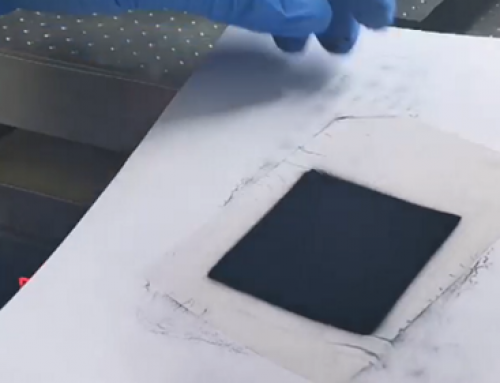

Microfluidic Chip Coating Video

https://www.youtube.com/watch?v=LAbWkcdSQpg