How Ultrasonic Nozzles Work

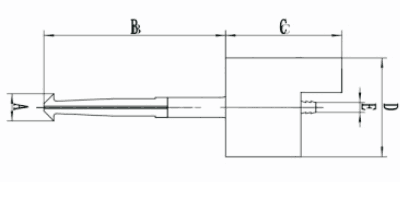

Each ultrasonic nozzle operates at a specific frequency, which determines the droplet size. The nozzles are made of very high strength titanium and stainless steel, making them extremely chemically resistant and providing excellent performance. The introduction of liquid into the atomizing surface by a non-clogging feed tube extending along the length of the nozzle creates vibrations in the liquid on the atomizing surface. In order to atomize the liquid, the amplitude of the vibration of the atomized surface must be carefully controlled. Below the so-called critical amplitude, the ultrasonic energy is insufficient to produce atomized droplets. If the amplitude is too high, the liquid is torn and a large amount of “fluid block” is ejected. The low-speed fine mist characteristic of ultrasonic spraying is produced only in a specific narrow range.

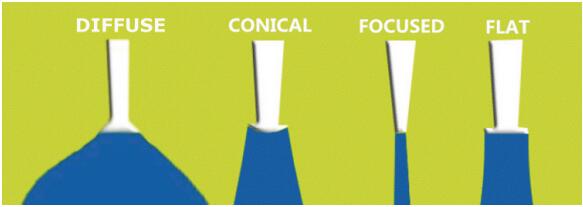

The nozzle shown above has a tapered atomizing surface for the purpose of dispersing the spray. Some applications require a very narrow spray, in which case the nozzle surface is flat. The nozzle surface is basically divided into the following three types according to the width requirement of the spray pattern and the required flow rate.

The leftmost figure in the above figure shows that the atomizing shape of the scattering type ultrasonic nozzle is tapered. Normally, the atomizing spray diameter is 50.8 – 76.2 mm.

The central illustration shows that the focused ultrasonic nozzle has a small cylindrical shape, and this type of ultrasonic nozzle has a spray diameter range of 0.381 to 1.016 mm. Usually we recommend this type of nozzle for low spray flow, low spray rate, and narrow spray.

The rightmost figure shows that the planar ultrasonic spray atomization shape is cylindrical, and the spray mode flow rate and spray rate are relatively high, but the lateral spray range is limited compared to the scattering type ultrasonic nozzle.