Nanosuspension

Ultrasonic sprayers are particularly suitable for spraying nanosuspensions due to the inherent ultrasonic vibration of the nozzle during atomization. The ultrasonic energy imparts continuous mechanical vibration to the nozzle, which separates the agglomerated particles in the nanosuspension throughout the coating process. Ultrasonic spray systems are simpler and more cost effective than other deposition methods such as CVD or vapor deposition, enabling low speed spray to reduce overspray of expensive materials.

Applications

• Deposit carbon nanotubes (carbon nanotubes), nanowires, perovskite materials, and graphene in a uniform thin coating to replace energy, electronics, semiconductor or medical applications.

• Spray catalyst inks such as carbon black and platinum solution in fuel cell manufacturing.

• Use graphene or carbon nanotubes for protection and strengthening applications.

• Various nano materials for EMI shielding.

• Create a transparent conductive coating.

• Deposition of uniform nanowires or graphene films in advanced electronic applications.

Ultrasonic coating systems are used to deposit nano-layer coatings with uniform thickness on substrates of any width. Even over a wide width, very thin coatings with high uniformity can be produced, which makes ultrasonic spraying technology particularly suitable for many precision nanotechnology spraying applications.

Features & Advantages

• Full range of ultrasonic nozzles

• Titanium alloy and stainless-steel construction, corrosion resistance

• The nozzle is not easy to be blocked

• Utilization> 95%

• Low diversion pressure can reduce waste of overcoating and air pollution

• Spraying proton exchange membrane with high uniformity and good adhesion

• Ultrasonic dispersion liquid system- keep the suspension evenly dispersed during spraying

• The particle diameter is optional which can more flexibly affect the through-hole property of the coating

• Heating plate, vacuum plate or combination of heating plate and vacuum plate

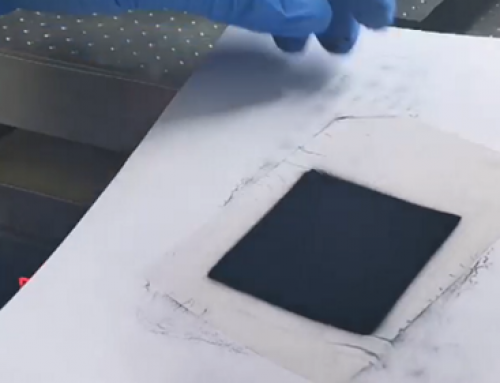

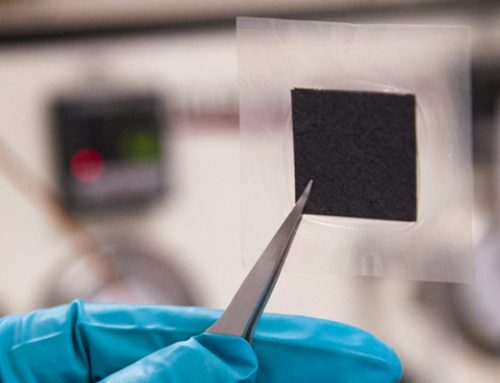

Coating Graphene Solution Video

https://www.youtube.com/watch?v=_j0mneo57nc