Touch Screen Coating

The ultrasonic spray coating system of Cheersonic is applied to the preparation of various functional nano films for glass surface such as hydrophilic and hydrophobic coatings, anti-reflection films coatings, light blocking coatings, transparent conductive oxide coatings, electrochromism coatings, photoresist coatings, high hardness and scratch-resistant coatings. Cheersonic is experienced in the preparation of film coatings for flat glass, such as architectural glass coatings, solar cell glass coatings, display glass coatings and etc. Ultrasonic spray has significant advantages over other coating methods for functional glass coatings such as Transparent Conductive Oxide coatings. Ultrasonic nozzles are uniquely suited to spraying suspensions with electrically active particles, dispersing them particles in suspension uniformly to produce excellent electrical properties.

Compared with the traditional air spray coating, ultrasonic spray coating has the advantages of high-precision control of film thickness, high uniformity, less spatter, and more than 4 times the utilization rate of raw materials. Compared with vacuum evaporation, CVD and other coating technologies, ultrasonic spray coating possesses a high cost performance, and the cost is greatly reduced for large-area coating. Thus ultrasonic spray coating is regarded as a new and scale technology of glass coating.

In addition, Cheersonic also provides complete ultrasonic spray coating units for glass coating equipment enterprises or existing glass coating production lines, including ultrasonic nozzles, ultrasonic controllers, liquid supply pumps, carrier gas control, etc., which can be directly and conveniently embedded into existing equipment production line, or developed secondarily.

Application of Ultrasonic Spray:

• Transparent conductive oxide coating

• Photoresist coating

• Electrochromic paint

• CNT or nanowire coating

• Anti-reflection (TiO2, SiO2) coating

Benefits of Ultrasonic Spray:

• Spray uniformity <5%.

• Utilization rate of solution reaches 95% and above.

• Very thin, uniform, durable layers

• Reliable, repeatable non-clogging spray

• Drastically reduced maintenance compared to pressure spray

• Virtually no overspray

• Spray width control for different width lites

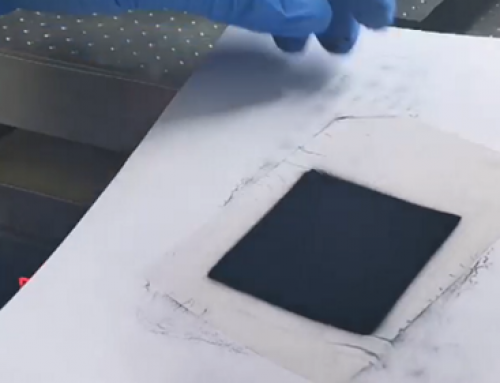

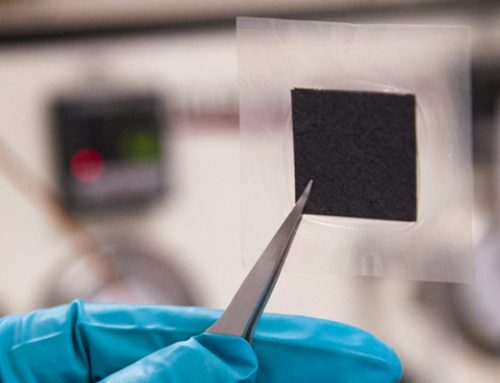

Glass Coating Video

https://www.youtube.com/watch?v=Am65nFKkUzo