Professional Coating Solution

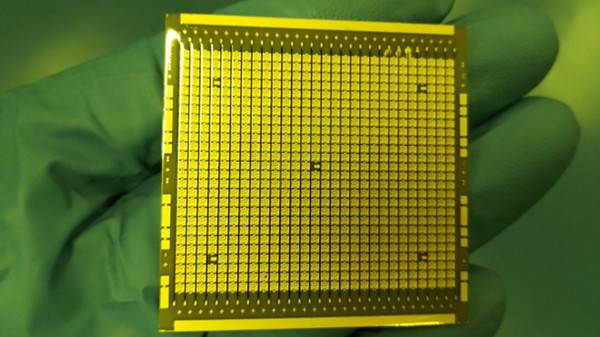

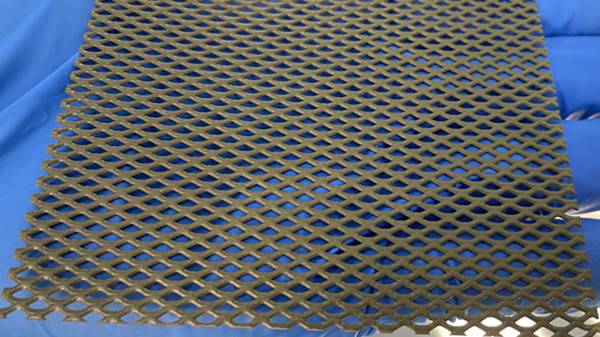

Cheersonic is the leading developer and manufacturer of ultrasonic coating systems for applying precise, thin film coatings to protect, strengthen or smooth surfaces on parts and components for the microelectronics/electronics, alternative energy, medical and industrial markets, including specialized glass applications in construction and automotive.

- – Advisory marketing

- – Targeted R&D

- – Refined production

- – Lifelong service

Our Company’s solutions are environmentally-friendly, efficient and highly reliable, and enable dramatic reductions in overspray, savings in raw material, water and energy usage and provide improved process repeatability, transfer efficiency, high uniformity and reduced emissions.

CHEERSONIC APPLICATIONS

ACCURACY

SUCCESS-RATE

BETTER DATA

COST-EFFECTIVE

Latest News

The following is the latest information and industry information of our company. We encourage customers to send samples for testing, and encourage customers to visit our corporate headquarters in Hangzhou, Zhejiang, China.

The change to Cheersonic has improved MEA fabrication efficiency, productivity, precision and reliability without any loss in fuel cell performances.

Easy company to work with, quality product.

Ultrasonic spray system is well, the effect of solder is very good, can continue to cooperate.

During the ultrasonic spray machine used for two months, although a bit of a problem, but had been solved timely, engineer is quite good.

Engineers and sales staff in high efficiency.

The engineer is very professional, ultrasonic spray system use effect is good.

Cheersonic is a supplier of an advanced coating system which can be modified according to customers requirements. The staff has a very professional way of handling sales, contracts, installation and following up.

Ultrasonic spray machine is good, easy to use.

Their machines are simple yet effective and can coat better than most traditional systems I’ve seen.

Trade Show

Cheersonic has participated in the following trade shows. Join and visit the Cheersonic team to see the latest and greatest ultrasonic spray equipment in one of these exhibitions near you.

Represented Globally

Cheersonic machines are being used in medical, electronics and energy production facilities around the world. Our sales and service representatives work closely with international distributors to ensure our customer’s success.