Metal Bipolar Plate Coating

Metals and alloys have good mechanical properties and electrical conductivity, and are cheap; passivation films are easy to form on the metal surface in the service environment. Although these passivation films slow down the corrosion rate, the conductivity of these passivation films is low, which leads to The output power and service life of the fuel cell are reduced. The conductivity and corrosion resistance of metal materials under service conditions are contradictory. How to solve this contradiction and achieve a reasonable match between the conductivity and corrosion resistance of materials is a major bottleneck in the improvement of metal bipolar plate technology. At present, the most effective way to solve the problem of conductivity and corrosion resistance is to modify the metal surface. The coated metal bipolar plate can improve the corrosion resistance of the bipolar plate while ensuring good conductivity, ensuring the entire The service life of the system is increased. However, the performance of the modified surface coatings of different metal materials is different. Therefore, choosing the right substrate and coating materials is the key to the wide application of metal bipolar plates.

Metal double standard plate base material

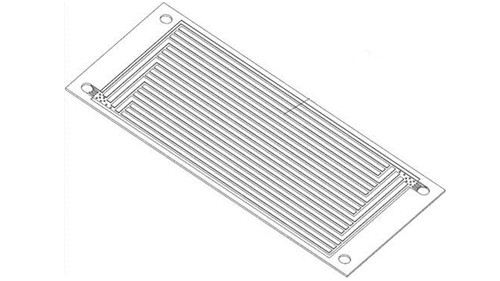

The base materials of metal bipolar plates mainly include stainless steel, aluminum, and titanium alloys. Such materials have high strength, good toughness, and good electrical conductivity and processing properties. For example, the conductivity of the metal bipolar plate can reach 10-100 times that of graphite, and due to its excellent mechanical properties, the thickness of the metal bipolar plate can be less than 1mm, which can greatly reduce the volume of the battery pack. However, metal materials are prone to corrosion in the battery environment (pH=2~3, T=80°C), resulting in a decrease in battery performance.

Although the metal bipolar plate has good strength, it can basically meet the mechanical performance requirements of the bipolar plate. However, the metal bipolar plate has poor corrosion resistance in the proton exchange membrane fuel cell environment, and the dissolved metal ions can poison the proton exchange membrane, resulting in a decrease in battery performance. The corrosion resistance of the metal bipolar plate can be improved by adding some alloying elements to the metal material. The reason is that these alloying elements will form oxides in the service environment. These oxides have an isolation and passivation effect on the metal surface and reduce the material. The corrosion rate. However, the low conductivity of these oxides reduces the output power and service life of the fuel cell. The material composition is different, the thickness of the oxide film formed on the surface is also different, and the order of increasing the thickness of the oxide film is basically the same as the order of increasing the contact resistance. It can be seen that while improving the corrosion resistance of the metal bipolar plate, its conductivity decreases, and the increase in corrosion resistance is inversely proportional to the decrease in conductivity. Although adding alloy elements to the metal can improve the conductivity of the passivation film, it cannot meet the performance requirements of the bipolar plate. Therefore, metal materials cannot be used directly as bipolar plates.

Metal bipolar plate coating material

In view of the contradiction between the conductivity and corrosion resistance of metal materials, the current solution is mainly to modify the surface of the metal bipolar plate, and the most researched is the metal surface coating. Since the mechanical and physical and chemical properties of the coating material and the metal and alloy substrate are different, it is necessary to select a coating material with good matching and bonding with the substrate to avoid electrochemical corrosion in the battery environment. Here, the coating materials are classified and introduced according to the stainless steel matrix and the lightweight metal and alloy matrix.

(1) Stainless steel bipolar plate coating

Stainless steel has excellent electrical conductivity/thermal properties, corrosion resistance and mechanical properties, and is the first choice for bipolar plate materials. However, this kind of material has poor corrosion resistance in the battery environment, and the conductivity of the passivation film formed on the surface is low. When the contact resistance increases by 25mΩ·cm2, the battery power will lose 2% to 5% [16]. How to choose the appropriate coating or adopt the appropriate surface treatment method to improve the corrosion resistance and chemical stability of the stainless steel bipolar plate while reducing the contact resistance has become the key technology of research and development. Stainless steel coating materials mainly include graphite, conductive polymers, metal nitrides, metal carbides, and precious metals.

Currently commonly used stainless steel materials mainly include SS304, SS316 and SS446 alloys. The corrosion current density of the uncoated SS304 stainless steel substrate in the battery environment is 2.6μA/cm2, and the contact resistance is 140mΩ·cm2; when the NbC layer is coated on the SS304 substrate, the corrosion current density and contact resistance can be reduced respectively To 0.051~0.058μA/cm2 and 8.47mΩ·cm2, the corrosion resistance and conductivity of the SS304 matrix are significantly improved. When the surface is coated with a layer of high molecular polymer (such as polypyrrole or polyaniline), its corrosion current density and contact resistance will be further lower than that of the coating NbC (corrosion current density is 0.1~1.0 μA/cm2, contact resistance is 0.08~1.0mΩ·cm2).

(2) Light metal bipolar plate coating

As light metals, titanium and titanium alloys, aluminum and aluminum alloys have the characteristics of high specific strength, good thermal and electrical conductivity, and easy processing. They are good materials for making bipolar plates. They have an advantage in improving the specific power of battery packs, and are especially suitable Bipolar plates for special purpose proton exchange membrane fuel cells. Here, we mainly introduce aluminum alloy base and coating materials and titanium alloy base and coating materials.

① Aluminum alloy substrate and coating

Compared with stainless steel, Al alloy has the advantages of low density (65% lighter than stainless steel), low resistivity (1/5 of stainless steel), high thermal conductivity (8 times of stainless steel), and easy processing. The corrosion resistance in the environment is poor and cannot meet the performance requirements of the bipolar plate. Therefore, the Al alloy must be surface treated to be used on the bipolar plate.

②Titanium alloy substrate and coating

Titanium alloy materials have the advantages of low density, high specific strength, corrosion resistance, and easy processing. However, passive films will also form on the surface of titanium alloys under high temperature or acidic conditions, resulting in increased contact resistance between the membrane electrode diffusion layer and the bipolar plate. Large, reduce the output power of the fuel cell. Since a passive film with low conductivity is easily formed on the surface of titanium alloy, titanium alloy cannot be directly used as a bipolar plate. Similar to stainless steel and aluminum alloys, titanium alloys can be coated on the surface to improve their corrosion resistance and electrical conductivity to meet the performance requirements of bipolar plates. In summary, titanium alloys and stainless steels are more suitable as bipolar plate base materials than Al alloys.

Preparation of Fuel Cell Bipolar Plate Coating

Ultrasonic spraying technology can prepare carbon-based catalyst coatings with high uniformity and high density, such as depositing platinum carbon, palladium carbon, ruthenium carbon and other catalyst coatings on Nafion proton exchange membranes, which are dense and uniform without swelling. Therefore, the ultrasonic spraying technology has been widely regarded by the industry as the key preparation technology of the membrane electrode of the proton exchange membrane fuel cell. Ultrasonic spraying equipment can be sprayed on a variety of different metal alloys, including the preparation of platinum, nickel, iridium and ruthenium-based fuel cell catalyst coatings, as well as PEMs, GDLs, DMFCs (direct methanol fuel cells) and SOFCs (solid oxide fuels) Battery). The battery manufactured by this technology has the characteristics of high battery load and high battery efficiency.