Ultrasonic Printed Circuit Board Flux Spraying

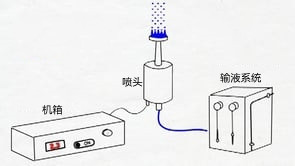

Ultrasonic Printed Circuit Board Flux Spraying. The principle of ultrasonic atomization: the ultrasonic chassis converts the mains into high-frequency electric energy. When the high-frequency electric energy reaches the transducer, it is converted into vibration mechanical energy of the same frequency by the transducer. The mechanical energy of the vibration breaks the liquid into UM-level droplets.

Ultrasonic advantages:

1. Reduce waste

2. Relatively environmentally friendly

3. The coating thickness is controllable

4. Not easy to block

At present, the frequency of 60KHZ is mainly used in the field of glass application, and the UAM4000L desktop type ultrasonic precision spraying machine can be used.

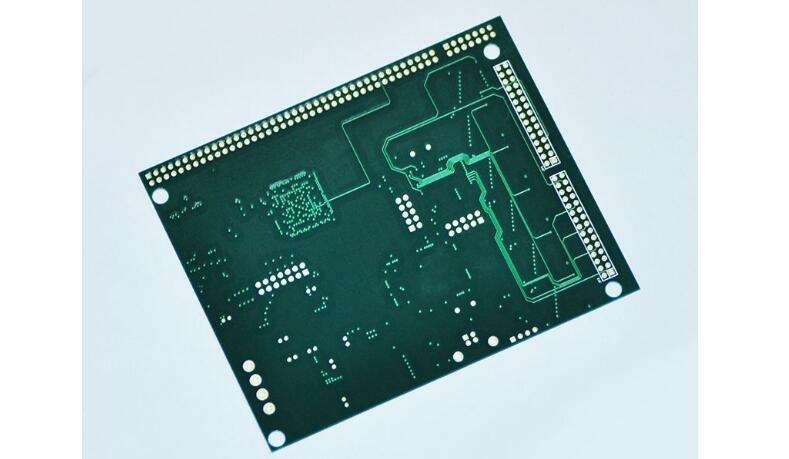

Printed circuit boards are also known as printed circuit boards. The insulating plate is cut into a certain size, and a conductive pattern is attached thereon, and a hole is arranged to replace the chassis of the electronic component of the conventional device, and the interconnection between the electronic components is realized.

Flux: Flux is a mixture of rosin-based components, a chemical that promotes soldering. It is corrosive.

Advantages of ultrasonic spraying: Flux is corrosive and pollutes the environment. The traditional high-pressure spray produces sputtering, and the ultrasonic gentle spray process does not sputter, reducing environmental pollution.

Ultrasonic Spray Video

Recommended Equipment

Ultrasonic Atomization Nozzle

Laboratory Ultrasonic Coating System

UAM3000 Ultrasonic Medical Devices Spraying

UAM4000 Desktop Ultrasonic Spraying Equipment

UAM4000L Benchtop Ultrasonic Spray System

UAM6000 Ultrasonic Spraying Machine

UAL100 Ultrasonic Dispersion Syringe Pump

LULP500 Ultrasonic Laboratory Device

Prosonic1000 Industrial Ultrasonic Device

Prosonic3000 Most Powerful Ultrasonic Processor