Membrane Coating System

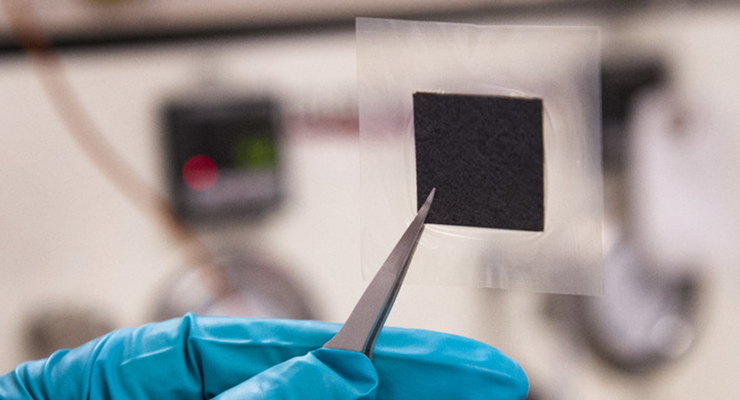

The most expensive component of a fuel cell is the membrane electrode assembly (MEA), which consists of an ionomer membrane coated with catalyst material. Best-performing MEAs are currently fabricated by depositing and drying liquid catalyst ink on the membrane. A automatic coating can reduce the cost and time needed to fabricate the MEA, incentivizing the commercialization and widespread adoption of fuel cells. A pilot-scale membrane coating system was designed for such a task and is described in this paper.

Fuel cell catalyst coating systems are particularly suitable for these challenging applications by creating highly uniform, repeatable and durable coatings. From R&D to production, our anti-clogging technology can better control coating properties, significantly reduce material usage, and reduce maintenance and downtime. Ultrasonic spraying of other metal alloys, including platinum, nickel, iridium and ruthenium-based fuel cell catalyst coatings of metal oxide suspensions, can be used to manufacture PEM fuel cells, polymer electrolyte membrane (PEM) electrolyzers, and DMFC (direct methanol fuel). Battery) and SOFC (Solid Oxide Fuel Cell) can maximize load and battery efficiency.

Ultrasonic Fuel Cell Coating Video

https://www.youtube.com/watch?v=ovkKTKtaUw4

Recommended Machine

UAL100 ultrasonic dispersion liquid supply system

UAM3000 Ultrasonic Bracket Spraying Machine

UAM4000 small desktop ultrasonic spraying machine

UAM4000L Ultrasonic Precision Spraying Machine

UAM6000 Ultrasonic Large Spraying Machine

UAM7000 Ultrasonic Balloon Guide Wire Spraying Machine

UAM8000 ultrasonic assembly line spraying machine